This post is part of our winter 2019 blOAAg series, Housing Affordability: Built-Form Case Studies. The featured case studies are from the OAA’s 2019 report titled, Housing Affordability in Growing Urban Areas, produced by the OAA’s Housing Affordability Task Group and SvN Architects + Planners.

Case Study 04: Carmel Place (formerly known as My Mirco NY) | Architect: nARCHITECTS

Location: New York City, USA | Year: 2013 - 2016

Program: 55 micro-unit apartments + retail | Size: 3250 sqm

Carmel Place (formerly known as My Micro NY) is the winning proposal in the adAPT NYC an initiative launched as part of former Mayor Bloomberg’s administration’s New Housing Marketplace Plan to accommodate the city’s growing small household population. The building was granted several mayoral overrides to allow this prototype to be built, including a relaxation of the minimum unit size, and the maximum density, or number of units permitted in a building. The now completed Carmel Place provides 55 loft- like rental apartments, ranging in area from 24-33 sqm (260-360 sf net, and complemented by generous shared amenities, setting a new standard for micro-living.

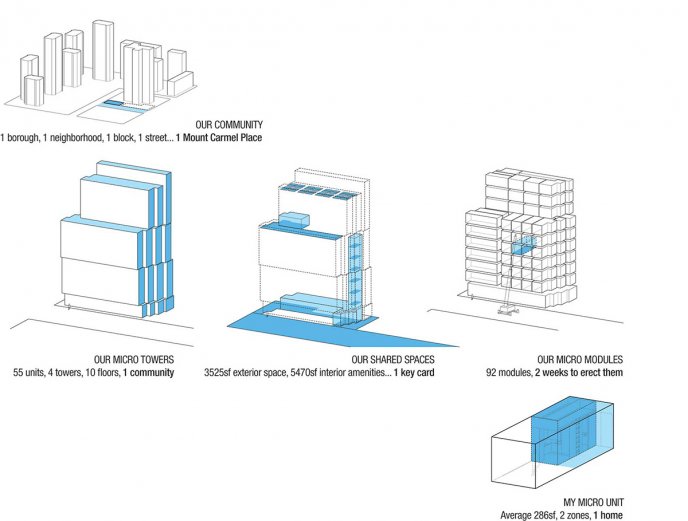

Concept diagrams, Carmel Place | nARCHITECTS

40% (22) of the 55 rental units at Carmel Place are dedicated for a housing, of which eight are Section 8 - reserved for formerly homeless US veterans (these apartments will be provided with complementary integrated furniture). The completion of model units earlier in 2016 generated a wide interest in Carmel Place, drawing in more than 60,000 applications for the 14 remaining affordable units.

The remaining 33 units are market rate; half of which include furniture and concierge services, an upgrade made possible for any of the units.

Concept diagrams and floor plans, Carmel Place | nARCHITECTS

In addition to being the first micro-unit apartment building in New York City, Carmel Place is - at the time of writing - the tallest modular building in Manhattan, and one of the first multi-unit Manhattan buildings using modular construction. Construction of Carmel Place consisted of fabrication, transportation and stacking of 65 individual self-supporting steel framed modules; 55 of which serve as residential micro-units, while the remaining 10 serve as the building’s core. The modules were pre-fabricated locally in the Brooklyn Navy Yard at the Capsys factory, while the foundation and ground floor were built on site.

Carmel Place | nARCHITECTS | Photography credits: Field Condition and Iwan Baan

Source: http://narchitects.com/work/carmel-place/

Photography Credits:

Field Condition | http://fieldcondition.com/

Iwan Baan | https://iwan.com/

_________________________________________________________________________________________________________

Official release date of the full report to be announced shortly.

The report, Housing Affordability in Growing Urban Areas, was prepared by SvN Architects + Planners Inc. (John van Nostrand, Liana Bresler and Blair Scorgie with the support of Eric Pitre and Jorge Quesada Davies), with the direction and assistance of the OAA Housing Affordability Task Group.