Straw Bale Children's Teaching Kitchen

BY: PETROFF PARTNERSHIP ARCHITECTS

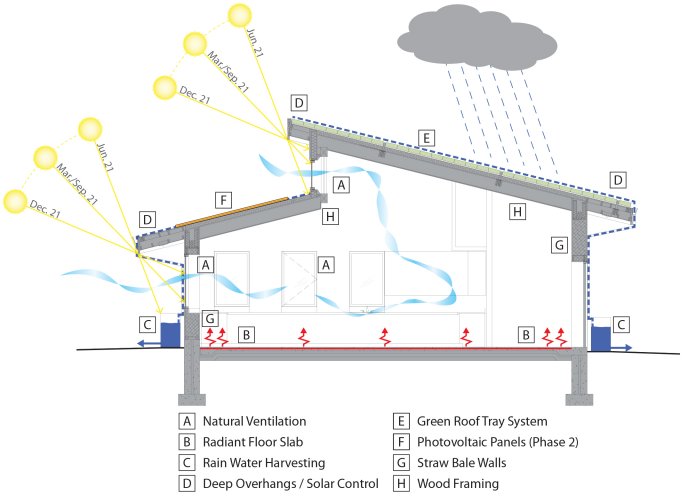

Solar control with clerestory windows and deep roof overhangs. © Photography H

Project Name: Straw Bale Children’s Teaching Kitchen

Project Owners: City of Toronto, Parks, Forestry & Recreation

Project Location: 105 Colborne Lodge Road, High Park, Toronto, ON

Architects: Petroff Partnership Architects

Project Completion Date: May 18, 2012

Project Site: Previously developed land

Project Type: K-12 Education, Higher Education, Restaurant, Recreation.

Project Type Context/Setting: Urban Park

Other Building Description: New

Lot Size: 447 m2

Building Gross Floor Area: 77.59 m2 / 835 sq ft

The Straw Bale Children’s Teaching Kitchen is located within High Park in Toronto, Ontario. The site is home to the park’s children’s garden and hosts over 5000 participants annually. The kitchen supports city operated programs that are held in conjunction with the adjacent garden, including school and family programs, workshops, eco-camps, community events and training.

The building was designed with the intention of creating a unique educational model of sustainable architecture and construction in Toronto. The project shows how coupling traditional building methods with new technologies can provide a highly efficient, green building.

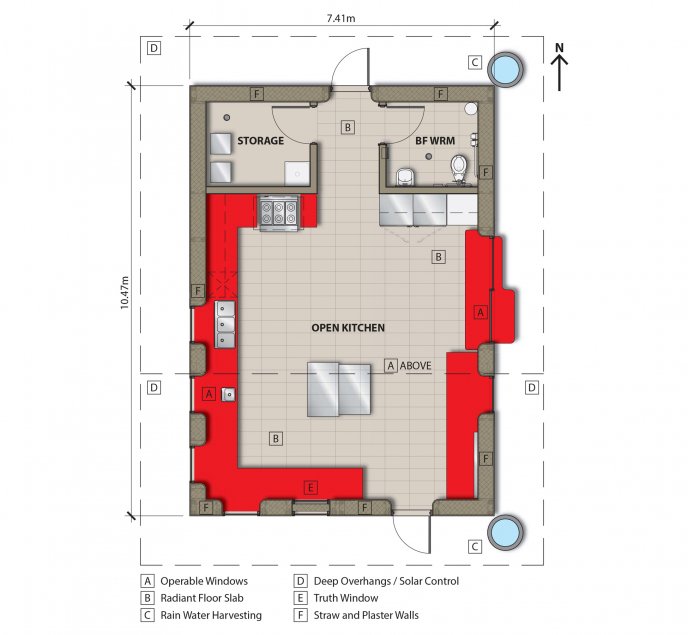

The existing picnic shelter footprint governed the development of the program in order to avoid disturbing existing landscape and ecosystems. The Straw Bale Children’s Teaching Kitchen consists of three spaces, an open kitchen area, barrier free washroom and storage room. The kitchen is fully equipped for preparation and cooking activities, which previously needed to be done off-site. A single location for planting, growing, preparation, cooking, eating and finally composting, gives the community a field-to-table-to-field educational experience.

Straw bale construction for a commercial kitchen created challenges while exhibiting the versatility of the material. The project demonstrates that straw and plaster can provide both fire resistance and moisture control. The kitchen establishes that straw is not limited to residential construction and has uses in other building types.

Sustainable Metrics

-

Annual Energy Consumption: 16518.59 ekWh/year

-

Energy Use Intesity: 212.89 ekWh/m2/year

-

Building Full Time Population: 3 People

-

Building Visitor Population: 27 People

-

Percentage reused materials: 60% of existing concrete slab

-

Percentage recycled material content: 10%

TOP

Straw bale wall construction prior to plastering. © PPA

Straw is a by-product of cereal grain harvesting such as wheat, oat, spelt or even hemp. This renewable resource is otherwise minimally used for biofuels, animal bedding or feed. The remainder is waste and frequently burned allowing pollutants to enter the atmosphere. It is rarely tilled back into the ground due to its naturally decomposition resistant properties. This creates an abundant waste material with excellent thermal properties that is highly suitable for construction. Therefore straw bales were chosen for the construction of the exterior walls.

Post and beam walls with straw bale infill outweighed the Nebraska style load bearing walls for this project. The schedule of the project did not permit inclement weather to delay the construction of the walls. Using a post and beam building allowed the roof to be built first in order to protect the straw from moisture while raising the walls. The straw was delivered to site with 12%-16% moisture content and precautions were taken to ensure the moisture content did not increase. The straw was delivered and stored on site once the roof was complete and the building was tarped until the straw bales were installed and plastered.

The site is located along a prominent route in High Park. This played an integral part in the aesthetic decisions for the project. The kitchen needed to be bright and uplifting, yet suited to the natural surroundings. Therefore a mix of natural materials and bright lively tones of green and yellow emerged.

One main decision was to maintain the existing building footprint of the picnic shelter to minimize the impact on the site, thus defining the shape of the plan. The building section is derived from a passive design strategy in order to optimize the use of natural light and cross ventilation.

A truth window was incorporated into the most prominent corner of the building and can be seen from the interior and exterior. The truth window displays the layers of straw bale construction as an educational tool for visitors to the site.

Truth window displaying the layers of the wall system. © PPA

TOP

Children participating in community garden and cooking programs. © City of Toronto

Children participating in community garden and cooking programs. © City of Toronto

The new kitchen allows the City of Toronto to provide community education workshops on green technology and energy conservation. In this case, the building would become a teaching example, where the community can learn about green technologies that can be incorporated into their own homes, such as solar or water harvesting.

The kitchen supports city operated programs that are held in the adjacent children’s garden, including school garden/nature programs, family garden drop-ins, eco-camps, workshops and community events. Other programs include city-wide training for city staff in ecology, organic gardening and children’s environmental programming.

There is no vehicular parking at the kitchen and limited parking within High Park. Public transit services the perimeter of the park, and there is seasonal transportation within the park. Bicycle racks are provided to compliment the many bike trails throughout the park.

The cooking for the children’s garden community events and programs previously needed to be done off-site. The new kitchen facility significantly reduces the amount of automobile travel for staff and community, because the growing, cooking and education can be done in one location. The new kitchen helps to provide the community with a field to table education, from the planting and growing, to cooking and eating and finally composting organic waste back in the garden.

A barrier free service counter and washroom is incorporated into the design to provide access for anyone to take part in the community programs. The adjacent children’s garden is also wheelchair accessible and hosts special needs groups annually.

Children’s gardens adjacent to new teaching kitchen. © City of Toronto

View of East elevation from children’s garden. © PPA

Site map. © grenadiercafe.com

TOP

Site plan. © PPA

The project ensured that the new footprint would be identical to the previous picnic shelter. This allowed for minimal site impact and preservation of the existing site features, such as the adjacent gardens and landscaping.

The mature black oak tree on the property was preserved with hoarding at the drip edge to prevent accidental damage to the crown or soil compaction around the roots.

Silt and sediment controls were implemented during construction in order to prevent any runoff into Grenadier Pond.

The project maintained the existing 71% of open landscaping in order to preserve the existing rate of water infiltration.

70% of the kitchen’s roof is covered with pre-planted green roof trays which reduce water runoff. The remainder of the water is collected in rain barrels to reduce flooding and provide a source of water for the adjacent children’s garden. The green roof also provides a new habitat for butterflies and other insects.

Before: Existing picnic shelter prior to demolition. © PPA

After: New kitchen occupying same footprint of picnic shelter. © Photography H

TOP

Deep overhangs shade the windows. © PPA

The climate for the project is variable, with warm, humid summers and cold winters. We addressed the climate with a simple building section, open plan and operable clerestory windows. These provide a passive design that utilizes natural light, solar heat gain or cross ventilation to reduce energy consumption for lighting and HVAC.

Operable windows on the East and West elevations allow air movement from prevailing winds to enter or pass through the building and expel hotter air through the clerestory windows.

Deep overhangs shade the South and West facing windows during the summer while allowing optimal light and solar heat gain during the colder months. The overhangs were designed to aid the building in controlling the interior environment. Thus reducing the heating load and eliminating the need for mechanical cooling system.

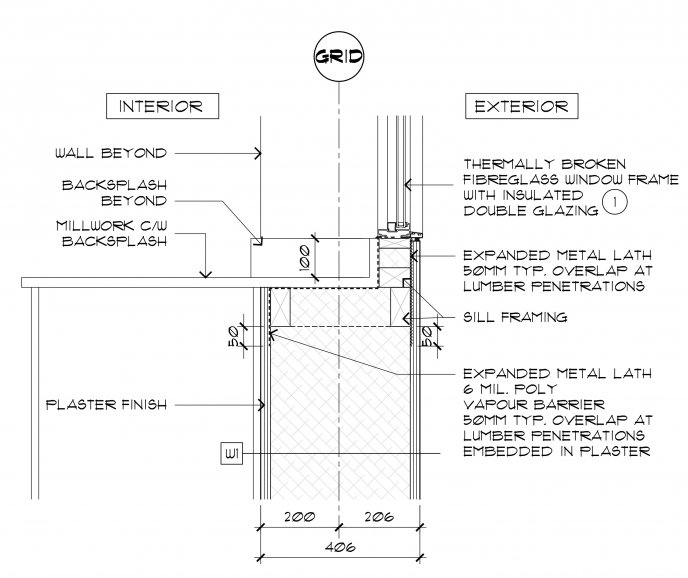

The South and West glazing coupled with the porcelain floor tiles on the concrete slab provide excellent thermal mass and helps to regulate daily temperature swings. Also, the straw bale walls are finished with 25mm of cement-lime plaster, which provides the kitchen with additional thermal mass over a vast exposure area.

Passive design strategies diagram. © PPA

Building Elevations. © PPA

Building Floor Plan. © PPA

TOP

Interior kitchen space. © Photography H

The small building footprint and open plan allows for 100 percent of the occupied floor area to be within 7 metres of multiple operable windows.

Operable clerestory windows provide additional light deeper into the space while providing natural ventilation during the summer.

Compact fluorescent light fixtures were chosen for reducing the overall energy consumption from artificial lighting. Occupancy sensors are used in the washroom and storage room to prevent energy waste, and a timer ensures outdoor lights are not operating during daylight hours.

Non-toxic, no or low VOC paints and sealants were used for healthier indoor air quality.

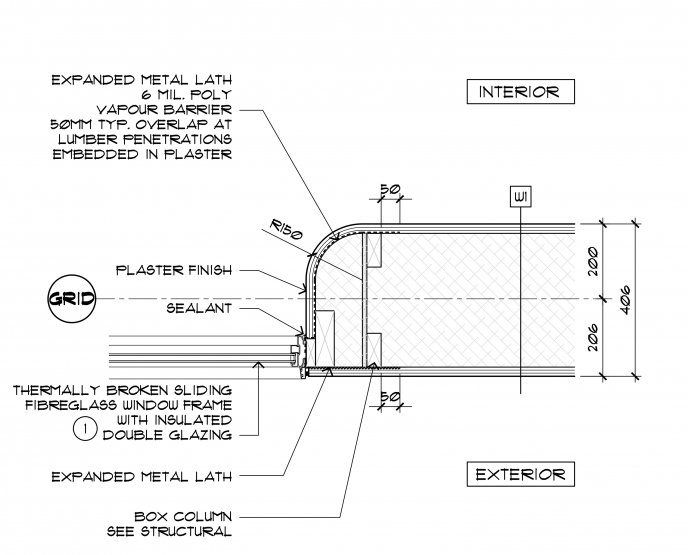

The faces of the exterior walls are coated with 25mm thick cement-lime plaster. The plaster acts as an air barrier, preventing air movement through the wall. The water resistance of the plaster is increased by adding a water repelling silicate dispersion paint that permits vapour transmission but prevents water drops from entering the wall system. Straw bale walls must be permitted to wick and dry by diffusion to the interior and exterior. It is for this reason that straw bale walls do not have a vapour barrier.

The combination of breathable paint, porous plaster and straw provide for significant hygroscopic capacity, mitigating typical daily and even seasonal indoor relative humidity swings. In the summer this contributes to “conditioning” the air by removal of high ambient humidity, while in the winter the reverse is true, leading to improved occupant comfort and reducing mechanical demands to perform the same work.

TOP

Left: Rainwater is harvested into two 500 litre barrels. © PPA. Right: Green roof tray system on the upper roof. © City of Toronto

Rainwater is harvested from the entire roof surface. The building’s lower sloping roof provides 37 square metres of roof area for rain water harvesting. This results in approximately 400 litres of water per typical rainfall. The higher roof consists of green roof trays and any excess runoff is also harvested.

Drought resistant plants were selected for the green roof trays so that no additional irrigation was required. Any of the rainwater collected into the two 500 litre rain barrels can therefore be used for the irrigation of the children’s garden.

The project uses water conserving automatic plumbing fixtures which use 46% less water than standard fixtures.

Hardscape on the site was limited around the building to maintain the existing site drainage and rate of water infiltration into the surrounding landscape.

TOP

Interior Kitchen Space. © Photography H

One of the challenges to designing a smaller structure that uses commercial grade appliances, and has a high ratio of building envelope per square meter, is ensuring that energy use intensity remains low. The unique programming and use of the Straw Bale Teaching Kitchen means that it could potentially be benchmarked against several categories of building types. When compared to the Canadian Commercial Regional Averages in the “Educational Services” building category, the project shows to be 50% more energy-efficient than other comparable special-use classrooms.

The kitchen incorporates an energy recovery ventilator to reduce energy consumption for preconditioning incoming fresh air.

The windows in the building are constructed with fibreglass frames, which provide excellent thermal properties, compared to aluminum or vinyl, without the need for thermal breaks.

The building incorporates a hydronic radiant floor which creates a comfortable warm surface and reduces the heating load on the HVAC system. The radiant floor could be converted to incorporate a solar water heating system in the event of a fossil fuel shortage.

The green roof system aids in reducing high temperatures during the summer months. This reduction, combined with the natural ventilation, removed the need for an additional cooling system. During the winter, vegetation helps trap snow, which adds insulation value to the roof and reduces heating loads.

Sustainable Metrics

Hydronic radiant floor heating system.© PPA

TOP

Straw bales installed in wood framing and sewn together. © PPA

The straw bales require no special treatment or industrial processing to render it suitable for insulative purposes. Only transportation, in this case from within 150km, and electricity to operate small tools were required to install the bales. The balance of all energy inputs for the bales, were renewable human labour, thus a significantly reduced embodied energy relative to typical exterior wall insulation.

The straw walls provide excellent thermal properties with a thermal resistance value of R37. Straw is a fast growing renewable resource that is typically unwanted and wasted. This building material can be grown locally and has one-twelfth the embodied energy of typical framing methods. The straw and plaster wall system also retains no moisture even without the use of vapor barriers.

The unique wood roof truss was hand built from white ash and cherry. The members were selected from structurally sound, less desirable wood that was bent or turned. These neglected individual pieces were combined to create a beautiful centrepiece for the interior of the building.

The framing system is constructed using built-up box posts and beams. These members consist of 2”x4”s connected together with 3/4” plywood. This allowed us to use smaller reforested trees for the framing system rather than larger timber framing. These structural members are also filled with straw to reduce the heat transfer through the framing.

The fibreglass window frames are resource efficient and contain a minimum of 10 percent of recycled content. They are non-toxic and do not emit VOCs. The frames have the lowest embodied energy consumption compared to traditional frames.

Since cement has high embodied energy, a portion of the existing picnic shelter concrete slab was preserved to reduce the amount of concrete required for construction of the new floor slab.

The sloping roofs are constructed with rafters supported on the exterior walls and central wood truss. The roof construction is a thermoplastic polyolefin white roof membrane on rigid insulation, vapour barrier and fibreboard. The pre-planted green roof tray system is placed over the roof construction on a root barrier. The green roof trays are manufactured with 100 percent of recycled materials and filled with plants grown at local nurseries.

Wood roof truss and clerestory windows. © PPA

TOP

Wood roof truss supporting upper and lower roofs. © PPA

The simple open program space allows for flexible use. The kitchen is adaptable for various community programs such as, eco camps, school nature/gardening programs, cooking classes, community events, garden drop-in programs, green energy workshops, environmental education, etc.

Providing a use for an otherwise waste material embraces a cradle to cradle way of thinking. The straw that would have been burned is reused for the construction of the kitchen walls.

The hybrid post-and-beam framing system allows ease of future changes to elements of the building envelope to allow for new or different openings. Straw can also be easily deconstructed from the framing system to accommodate change or can be reused as garden bedding.

The green roof over the roof membrane provides a barrier from ultraviolet rays, potential punctures and drying winds. This ultimately extends the service life of the membrane.

Straw bales stacked between wood post framing. © PPA

TOP

View of East elevation from children’s garden. © PPA

Research into straw bale construction detailing was crucial to the success of the building. A poorly detailed wall could cause the plaster to crack or moisture to enter creating significant problems. Having a straw bale consultant on board during design and construction proved to be extremely important.

It is important to integrate the bales and wood frame correctly to ensure there are minimal awkward fits between them which may increase projects costs or lengthen the schedule.

From a cost savings perspective, size the building based on framing and sheet goods rather than the straw bale module size. Straw bales will require adjustments or cutting even when the building is designed around them.

The project shows how combining traditional building methods with new technologies can provide a highly efficient, green building. The building is featured on the Ontario Straw Bale Building Coalition’s annual tour and continues to garner a great deal of public attention.

Plan detail at window jamb. © PPA

Section detail at window sill. © PPA

TOP

Southwest corner from Colborne Lodge Road. © Photography H

Design Architect: Petroff Partnership Architects

General Contractor: Joe Pace & Sons Ltd.

Civil Engineer (Grading only): Urbtech Engineering Inc.

Electrical / Mechanical Engineer: Jain and Associates Limited

Structural Engineer: Blackwell Bowick Structural Engineers

Owner/Developer: City of Toronto: Parks, Forestry and Recreation

Building Envelope / Straw Bale Consultant: Evolve Builders

Quantity Surveyor: A.W. Hooker Quantity Surveyors

Geotechnical Engineer: Forward Engineering & Associates Inc.

TOP